Tunnel linings are critical components in excavation projects, providing structural support and ensuring long-term stability. They are typically categorized into primary and secondary linings, each serving distinct purposes during and after construction.

The primary lining is the initial support system installed immediately after excavation. Its main function is to stabilize the newly excavated ground, prevent immediate collapses, and support the surrounding rock or soil mass.

Here are some key characteristics of primary linings:

Immediate Support: It's installed very close to the tunnel face as excavation progresses.

Temporary or Semi-Permanent: While it provides immediate support, it can be temporary and later supplemented or become part of the permanent structure, depending on the design.

Materials: Common materials include:

Shotcrete: Sprayed concrete that conforms to the irregular rock surface.

Steel Ribs (Lattice Girders): Structural steel elements that provide initial strength.

Rock Bolts/Dowels: Rods inserted into the rock to improve its stability.

Wire Mesh: Used in conjunction with shotcrete to reinforce it.

Purpose: To manage ground loads immediately after excavation, control deformation, and create a safe working environment.

Rough Finish: The finish is generally rough and uneven, as its primary concern is structural integrity, not aesthetics or waterproofing.

Secondary Lining

The secondary lining is the permanent, final lining installed after the primary lining is in place and the ground has reached a more stable state. It is designed for the long-term operational life of the tunnel.

Here are some key characteristics of secondary linings:

Permanent Structure: It forms the final interior surface of the tunnel.

Long-Term Functionality: Designed to resist long-term ground pressures, provide waterproofing, ensure durability, and offer an aesthetic finish.

Materials: Most commonly made of:

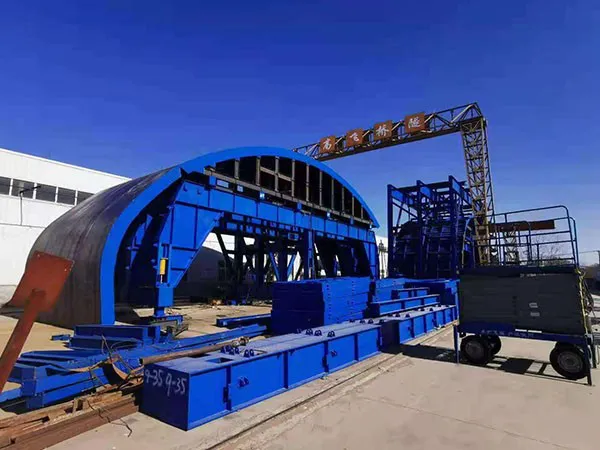

Cast-in-place Concrete: Poured concrete that creates a smooth, continuous surface.

Precast Concrete Segments: Manufactured off-site and assembled within the tunnel, often used in bored tunnels (e.g., TBM tunnels).

Purpose: To provide the ultimate structural strength, ensure waterproofing, create a smooth internal surface for operational efficiency (e.g., air flow, reduced friction), and offer protection against environmental factors.

Smooth Finish: Typically has a smooth, finished surface suitable for the tunnel's intended use, often including provisions for drainage and utilities.

Key Differences Summarized:

|

Feature |

Primary Lining |

Secondary Lining |

|

|

Timing |

Installed immediately after excavation |

Installed after the primary lining is in place |

|

|

Purpose |

Immediate ground stabilization, worker safety |

Long-term structural integrity, waterproofing |

|

|

Durability |

Temporary to semi-permanent |

Permanent |

|

|

Materials |

Shotcrete, steel ribs, rock bolts, wire mesh |

Cast-in-place concrete, precast concrete segments |

|

|

Finish |

Rough, irregular |

Smooth, finished |

|

|

Functionality |

Supports immediate loads, controls deformation |

|

In some modern tunneling methods, particularly with Tunnel Boring Machines (TBMs), the precast concrete segments installed directly behind the TBM can serve as both the primary and secondary lining, acting as the immediate support and the final, permanent structure. This is often referred to as a "single-pass lining."

Gaofei

Address: 200m east of tulip garden, group 12 of zhangling community, hongshan street office, hongshan town, xigong district, Luoyang

Tel: +8616638856888

Contact: Gaofei Huang

Mobile: +86-18637923976

Phone: 0379-80881719/ 0379-60162687

QQ: 286827457

E-mail: gaofei@gf-bridge-tunnel.com