Tunnel construction is one of the most technically demanding tasks in modern infrastructure engineering. From complex geological conditions to strict safety standards and long-term durability requirements, every design decision has a lasting impact on project success.

Among these decisions, selecting the right tunnel lining system is critical. An unsuitable lining solution can lead to structural risks, water leakage, excessive maintenance costs, or even premature failure of the tunnel.

In this guide, we break down the most common types of tunnel lining systems, compare their advantages and limitations, and help you determine which tunnel lining solution best fits your project conditions.

Initial support—also referred to as primary or temporary lining—is installed immediately after tunnel excavation. Its primary role is to stabilize the surrounding ground and prevent deformation or collapse during construction.

Typical materials include shotcrete, steel ribs, rock bolts, or timber frames, selected according to ground conditions.

Key advantages:

Provides immediate structural stabilization after excavation

Reduces construction-stage safety risks

Flexible application in varying geological conditions

Limitations:

Not designed for long-term structural performance

Usually requires a secondary lining for durability

Best suited for:

Soft soil, weak rock formations, and tunnels with high deformation risk.

Secondary lining is the final structural layer designed to ensure the tunnel’s long-term strength, durability, and waterproofing performance. It is typically constructed using reinforced concrete, cast-in-place concrete, or fiber-reinforced sprayed concrete.

Key advantages:

High load-bearing capacity and long service life

Excellent water tightness and structural integrity

Customizable geometry for complex tunnel designs

Limitations:

Longer construction time compared to temporary supports

Higher labor and material costs

Best suited for:

Urban tunnels, deep underground tunnels, and projects requiring high durability and waterproofing.

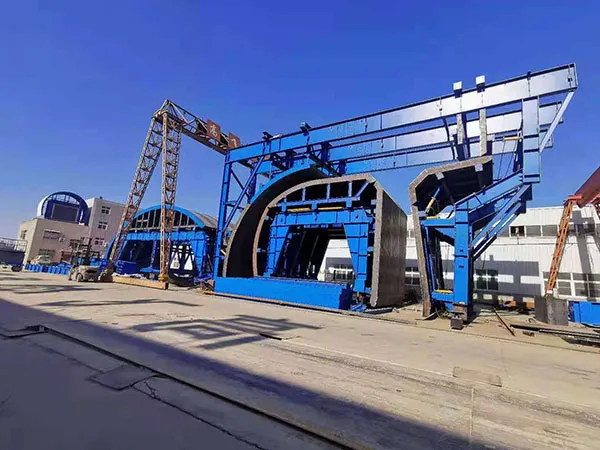

Precast segmental lining consists of factory-manufactured concrete segments assembled inside the tunnel to form a continuous ring. These segments are commonly installed using Tunnel Boring Machines (TBMs).

Key advantages:

Fast and highly efficient installation

Consistent quality under controlled manufacturing conditions

Excellent performance under high groundwater pressure

Limitations:

Higher initial investment

Requires precise installation and advanced equipment

Best suited for:

Long-distance tunnels, TBM-driven projects, and high water-pressure environments.

|

Lining Type |

Advantages |

Limitations |

Cost Level |

Service Life |

Construction Difficulty |

Typical Applications |

|

Initial / Primary Support |

Fast installation, immediate stabilization |

Temporary, limited durability |

Low |

Short-term |

Medium |

Soft soil, weak rock |

|

Secondary / Permanent Lining |

Long-term stability, waterproof, high load capacity |

Longer construction time |

Medium–High |

50–100+ years |

High |

Urban & deep tunnels |

|

Precast Segmental Lining |

Fast, high precision, mechanized |

Higher upfront cost |

High |

50–100+ years |

Medium |

TBM tunnels, high water pressure |

Selecting the optimal tunnel lining system depends on several key factors, including geological conditions, tunnel length, water pressure, and construction method.

Practical recommendations:

Soft Soil or Weak Rock:

Combine initial support with a secondary lining. Shotcrete or steel ribs ensure immediate stability, while reinforced concrete provides long-term strength.

High Groundwater or Water Pressure Zones:

Precast segmental lining offers superior waterproofing and resistance to hydrostatic pressure.

Urban or Deep Underground Tunnels:

Secondary lining is ideal due to its durability, structural reliability, and adaptability to complex tunnel geometries.

Long TBM-Driven Tunnels:

Precast segmental lining is preferred for its speed, safety, and consistent quality.

Choosing the correct tunnel lining system is essential for ensuring construction safety, cost efficiency, and long-term tunnel performance. By fully understanding the characteristics, advantages, and limitations of each lining type, engineers and project managers can make informed decisions that reduce risks and optimize project outcomes.

A well-matched tunnel lining solution not only improves construction efficiency but also extends the service life of the tunnel and minimizes long-term maintenance costs.

Gaofei

Address: 200m east of tulip garden, group 12 of zhangling community, hongshan street office, hongshan town, xigong district, Luoyang

Tel: +8616638856888

Contact: Gaofei Huang

Mobile: +86-18637923976

Phone: 0379-80881719/ 0379-60162687

QQ: 286827457

E-mail: gaofei@gf-bridge-tunnel.com