As global infrastructure construction continues to grow, the scale and complexity of tunnel engineering are also constantly increasing. From subway and railway tunnels to water conservancy projects and mining development, secondary lining construction has become a crucial step in ensuring the stability and durability of tunnel structures. In this process, the secondary lining trolley serves as core equipment, and its design specifications directly impact concrete pouring quality, construction efficiency, safety management, and project timeline and cost.

For engineering contractors, project managers, and equipment procurement personnel, a deep understanding of the design details and industry trends of secondary lining trolleys helps in making more valuable decisions during equipment selection and construction management.

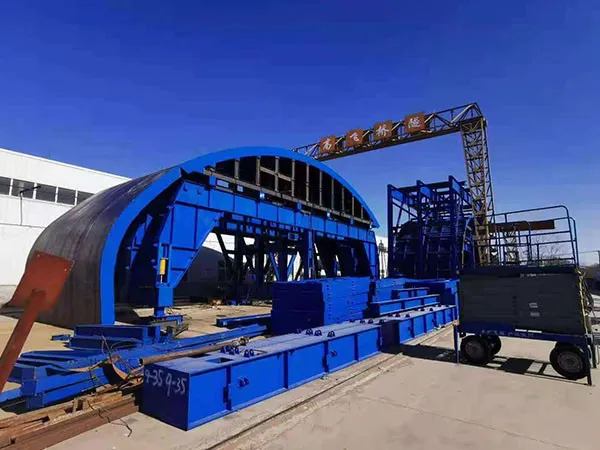

The main function of secondary lining trolleys is to support and fix the formwork system, forming a closed space for pouring concrete, and enabling the turnover of pouring cycles through hydraulic or mechanical structures. Compared to traditional manual formwork erection methods, modern mechanized trolleys have the following advantages:

High forming accuracy: Strong formwork stability, with errors controllable to the millimeter level;

Strong controllability of construction period: High mechanized turnover efficiency, enabling 1-2 cycles per day;

High level of construction safety: Reduces manual work at heights and high-risk operating positions;

Superior appearance quality: High lining flatness, better meeting long-term operational requirements;

Reduced rework and concrete waste.

The importance of secondary lining trolleys is further highlighted in scenarios such as long-distance tunnel construction, curved section construction, and ultra-large cross-section construction.

A stable and reliable secondary lining trolley consists of multiple functional modules, each of which directly affects the construction quality. 2.1 Main Load-Bearing Structure (Chassis & Frame)

The load-bearing structure is the core of the trolley, typically constructed using high-strength steel such as Q345 and Q460 to withstand the weight of the formwork and the lateral pressure from the concrete during pouring.

Structural Design Considerations:

A combination of box girders and H-beams enhances bending resistance;

Heavy-duty reinforcing ribs are placed at load concentration points to prevent fatigue cracking;

A fully welded structure is employed to improve overall rigidity;

Heat treatment is applied to the formwork support areas to strengthen them and prevent deformation caused by long-term use.

2.2 Rail System (Wheel & Rail System)

In tunnels, space is limited and gradients change frequently; therefore, the rail system must ensure stability and reliability.

Technical highlights include:

High-wear-resistant alloy steel solid wheels with strong impact resistance;

Conical guide wheels prevent derailment, especially suitable for construction on curved sections;

Adjustable wheel gauge mechanism adapts to tunnels with different cross-sections;

Low-noise bearings and lubrication system improve comfort and reduce maintenance.

At some modern construction sites, the manufacturer provides rubber-coated wheels or dual-mode wheels (rail wheels + rubber wheels) suitable for different ground conditions.

2.3 Formwork, Lifting & Positioning System

The formwork is a key component for forming quality; its structural design determines the flatness and dimensional accuracy of the lining.

A hydraulic lifting system enables the raising and lowering of the entire formwork unit;

A multi-point synchronous system ensures uniform stress on the formwork;

The formwork is composed of high-strength steel plates and a high-precision curved frame;

The outer surface is laser-cut to ensure the curvature perfectly matches the design drawings;

Sealing strips are installed at the formwork joints to prevent grout leakage.

For demanding municipal and railway projects, the formwork surface may even undergo polishing to ensure a fair-faced concrete finish.

2.4 Power Source

Depending on the construction environment, power systems can be categorized as follows:

Electric drive (suitable for tunnels with poor ventilation and high environmental requirements)

Diesel drive (suitable for short tunnels or well-ventilated environments)

Electro-hydraulic hybrid drive (higher control precision and smoother power)

As the industry transitions to green construction, electric trolleys are gradually becoming the trend.

2.5 Safety System & Operation Interface

Modern secondary lining trolleys feature increasingly sophisticated safety protection measures, including:

Emergency stop buttons (multiple locations)

Travel limit devices (mechanical + electrical dual)

Hydraulic system overflow protection

Formwork locking and anti-slip system

Fall-prevention guardrails and maintenance platform

The operating interface has also evolved from traditional button-based systems to PLC touchscreens + intelligent control, enabling more precise control and fault diagnosis.

When purchasing or customizing secondary lining trolleys, the following design specifications directly affect construction efficiency, operational safety, and service life.

3.1 Load Capacity

Load capacity calculations must consider:

Formwork self-weight

Concrete pouring volume per cycle

Hydraulic system reaction force

Dynamic load and inertial force

The mainstream design load capacity is 10–35 tons, and large high-speed railway projects can even reach over 50 tons.

3.2 Tunnel Compatibility

Modern secondary lining trolleys generally require compatibility with various tunnel cross-sections:

Circular tunnels

Horseshoe-shaped tunnels

Double-track tunnels

Secondary lining sections of segment-assembled tunnels

Height-adjustable structures, width-adjustable systems, and segmented splicing structures are becoming increasingly common in the industry, enabling trolleys to adapt to various working conditions and eliminating the need for frequent equipment changes.

3.3 Travel Speed and Pouring Cycle (Operational Speed)

Excessive speed can be dangerous, while insufficient speed impacts the construction schedule. Therefore, a high-quality trolley must achieve the following:

Stable low-speed mode: ≤1 m/min, for precise positioning

Standard forward mode: 2–6 m/min, improving construction rhythm

Continuous operation without slippage or bouncing

In long tunnel projects, travel efficiency directly affects the entire construction cycle.

3.4 Maintenance Access

The ease of maintenance of engineering equipment directly affects the total cost:

Critical lubrication points are located in easily accessible positions

Electrical components use standardized modules

The formwork system supports rapid assembly and disassembly

Each cylinder is equipped with a pressure gauge and independent valve group

Excellent design can reduce maintenance time by 20–40%, significantly reducing downtime risk.

With the development of intelligent manufacturing and engineering machinery, secondary lining trolleys are also moving towards a higher level of intelligence.

4.1 Automated Guidance

Modern systems often utilize:

Laser sensors

Gyroscopes

Route correction systems

to enable the trolley to automatically move along its trajectory, reducing manual intervention and improving accuracy.

4.2 Real-time Monitoring

With the increasing trend of digital construction management, more and more trolleys are equipped with:

Load monitoring

Real-time monitoring of oil pressure and temperature

Formwork position display

Grouting leakage alarm

Fault diagnosis logic

Data synchronization to the cloud

Making it easier to meet construction quality standards and increasing project management transparency.

4.3 Application of New Materials (Lightweight and High-Strength Materials)

Using new materials can significantly optimize equipment performance, such as:

High-strength steel structures increase load-bearing capacity while reducing weight

Aluminum alloy operating platforms reduce weight

Composite material formwork reduces deformation and maintenance needs

Lighter trolleys mean less energy consumption and faster movement efficiency.

An excellent secondary lining trolley can significantly improve the overall efficiency and safety of tunnel engineering:

Higher forming quality

More controllable construction period

Lower safety risks

Lower labor costs

Simpler operation and maintenance

For construction companies, choosing a trolley is not just an equipment purchase, but a long-term investment.

The stability, safety, and intelligence of the equipment directly affect the overall quality and economic benefits of the project.

As tunnel engineering develops towards higher standards and higher efficiency, secondary lining trolleys with advanced design, mature technology, and intelligent functions will become indispensable equipment in modern tunnel construction.

Gaofei

Address: 200m east of tulip garden, group 12 of zhangling community, hongshan street office, hongshan town, xigong district, Luoyang

Tel: +8616638856888

Contact: Gaofei Huang

Mobile: +86-18637923976

Phone: 0379-80881719/ 0379-60162687

QQ: 286827457

E-mail: gaofei@gf-bridge-tunnel.com