Tunnel lining is a critical component of underground engineering, ensuring the structural stability, watertightness, and long-term durability of tunnels. A comprehensive understanding of tunnel lining construction processes, materials, and best practices helps engineers and project managers mitigate risks and maintain high standards of quality. This article provides a detailed analysis of the tunnel lining construction process, highlights common challenges, and offers practical solutions to ensure successful project completion.

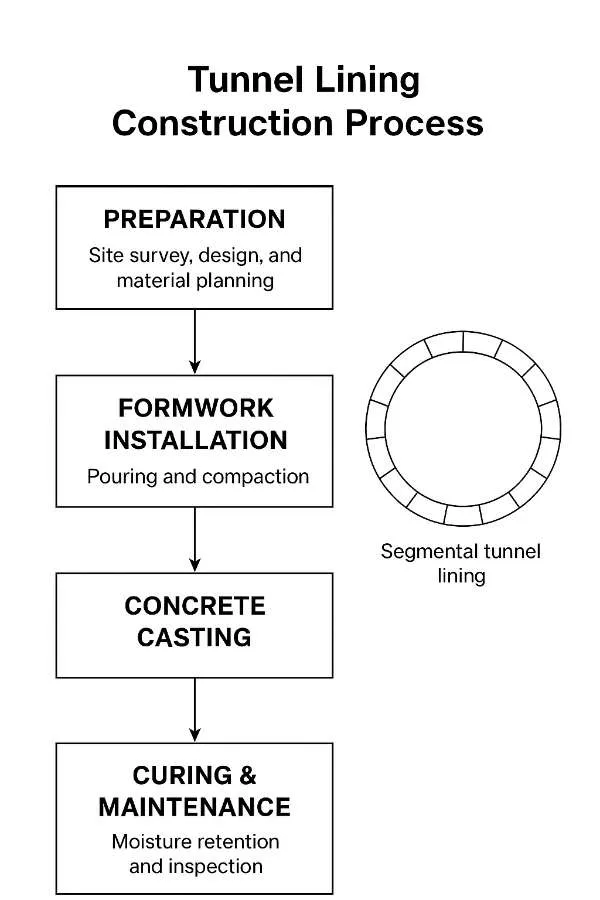

The first step in any tunnel lining project is careful preparation, which sets the foundation for safe and efficient construction. Key activities include:

Site Survey & Geotechnical Investigation: Understanding soil conditions, groundwater levels, and rock types helps in selecting appropriate lining methods and materials.

Design Verification: Confirming structural and hydraulic design parameters to ensure the lining can withstand anticipated loads and pressures.

Equipment & Material Planning: Ensuring timely availability of formwork, concrete, reinforcement, and curing materials to avoid delays.

Tip: Using 3D tunnel modeling software can help visualize lining segments and anticipate complex geometries, reducing errors during construction.

2. Formwork Installation: Building the Framework

Formwork or templates are essential for shaping the tunnel lining. Depending on the project, steel, timber, or modular formwork may be used.

Template Positioning: Proper alignment and anchoring are critical to avoid dimensional errors.

Reinforcement Placement: Steel rebar is installed according to design specifications, ensuring structural strength and crack resistance.

Quality Checks: Prior to pouring concrete, verify correct spacing, alignment, and stability of templates.

Concrete pouring is the most sensitive phase in tunnel lining construction. Best practices include:

Mix Design Compliance: Use high-performance concrete tailored for tunnel environments, considering compressive strength, workability, and water tightness.

Continuous Pouring: Avoid cold joints by ensuring uninterrupted concrete flow.

Vibration & Compaction: Proper consolidation reduces voids and enhances structural integrity.

Challenges to Watch For:

Segment Collapse: Insufficient support or poor-quality concrete can lead to temporary or permanent collapse.

Leakage: Improper sealing or mix design can cause water infiltration, especially in high groundwater conditions.

4. Curing & Maintenance: Strengthening the Structure

After concrete casting, curing is crucial for achieving long-term durability:

Moisture Retention: Cover the lining with wet burlap or apply curing compounds to prevent premature drying.

Temperature Control: Maintain proper temperature to avoid thermal cracking, especially in large-diameter tunnels.

Inspection & Repair: Conduct early inspections for cracks, voids, or surface defects and address issues immediately.

Pro Tip: Implementing automated monitoring systems can detect early-stage defects and water leakage, reducing maintenance costs.

Even with careful planning, several difficulties may arise:

|

Challenge |

Description |

Best Practice |

|

Collapse & Instability |

Weak soil or excavation errors can cause lining failure |

Use temporary supports, timely excavation, and real-time monitoring |

|

Water Leakage |

Groundwater infiltration through joints |

Employ waterproof membranes, sealants, or high-quality concrete |

|

Cross-Section Deviation |

Misalignment of segments affecting tunnel geometry |

Precision surveying, modular formwork, and frequent dimensional checks |

Ensuring tunnel lining quality requires a combination of technical expertise and strict process control:

Follow Standards: Adhere to local and international tunnel construction codes and norms.

Regular Testing: Concrete strength tests, waterproofing checks, and alignment measurements.

Documentation: Keep detailed records of materials, mix ratios, curing times, and inspections.

Safety Protocols: Protect workers from confined space hazards, falling objects, and dust exposure.

7. Conclusion

A successful tunnel lining project depends on meticulous preparation, precise execution, and strict quality control. By understanding the construction process, addressing common challenges, and applying best practices, project teams can deliver safe, durable, and leak-free tunnel structures.

Investing in process optimization and modern monitoring techniques not only reduces risks but also improves efficiency and project sustainability.

Gaofei

Address: 200m east of tulip garden, group 12 of zhangling community, hongshan street office, hongshan town, xigong district, Luoyang

Tel: +8616638856888

Contact: Gaofei Huang

Mobile: +86-18637923976

Phone: 0379-80881719/ 0379-60162687

QQ: 286827457

E-mail: gaofei@gf-bridge-tunnel.com